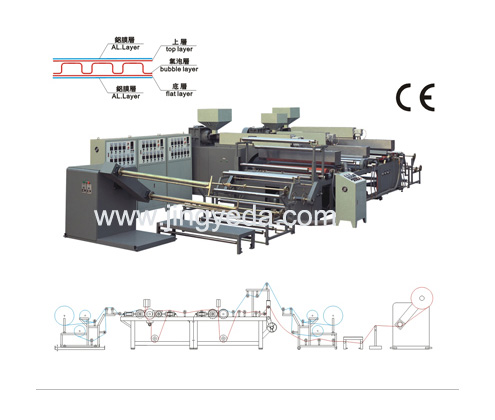

Air Bubble Film Extrusion Line

This extrusion line has 3 series: 1 extruder (2 layers), 2 extruders (double-side, 3 layers) and 3 extruders (7, 5, 3 layers).

Advantages:

1. Especially stable and no trouble.

2. Flexible to different original materials (LDPE,LLDPE and recycled).

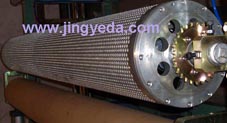

3. With different bubble roller,it may make bubbles of D7-30 mm. (Usually one bubble roller with the machine if not mention).

4. Inline coating system is optional.

5. With turret winding station.Easy to operate.

6. The machine is with both air cooling and water cooling. Water cooling is for better production efficiency and the bubble film is more transparent and with more 3-D feelig. Air cooling may fulfill requirments of no water.

7. V. F. drive for speed regulation and so power saving.

Single extruder (2 layers)

|

Model |

Material |

width mm |

Max Production |

Total Power |

Weight |

|

ABF-2400S |

LDPE |

2400 mm |

180 kg/hr |

150 kw |

6300 kg |

|

ABF-2000S |

LDPE |

2000 mm |

140 kg/hr |

108 kw |

5700 kg |

|

ABF-1800S |

LDPE |

1800 mm |

110 kg/hr |

85 kw |

5200 kg |

|

ABF-1600S |

LDPE |

1600 mm |

100 kg/hr |

65 kw |

4800 kg |

|

ABF-1500S |

LDPE |

1500 mm |

85 kg/hr |

65 kw |

4500 kg |

|

ABF-1200S |

LDPE |

1200 mm |

75 kg/hr |

55 kw |

4100 kg |

|

ABF-1000S |

LDPE |

1000 mm |

60 kg/hr |

53 kw |

3900 kg |

|

Double-extruder (3 layers) |

|||||

|

ABF-2400B |

LDPE |

2400 mm |

250 kg/hr |

220 kw |

7900 kg |

|

ABF-2000B |

LDPE |

2000 mm |

200 kg/hr |

165 kw |

7400 kg |

|

ABF-1800B |

LDPE |

1800 mm |

160 kg/hr |

135 kw |

6900 kg |

|

ABF-1600B |

LDPE |

1600 mm |

140 kg/hr |

105 kw |

6500 kg |

|

ABF-1500B |

LDPE |

1500 mm |

120 kg/hr |

105 kw |

6000 kg |

|

ABF-1200B |

LDPE |

1200 mm |

100 kg/hr |

90 kw |

5500 kg |

|

ABF-1000B |

LDPE |

1000 mm |

80 kg/hr |

80 kw |

5300 kg |

|

Double-side Air Bubble – Alu Extrusion Line |

|||||

|

Model |

Material |

Layer |

Width |

Production |

Weight |

|

ABF-1500DH |

LDPE |

3 |

1500 mm |

170 kg/hr |

105 kg |

|

ABF-1500TH |

LDPE |

5 |

1500mm |

250 kg/hr |

160 kg |